The original sawhorse design was a great one, the only things I really changed for the 2.0 version were the height of the horses, the width of the horses, and the width of the leg panels. The changes made now allow for nearly, if not all of the materials to be cut out of one sheet of plywood (on the computer it says it can be done, but when I tried I failed somehow). The working height could be lowered still to enable you to get everything out of one piece except for the 2x4 top piece, but that would lower the working height to a level to low for my personal preference.

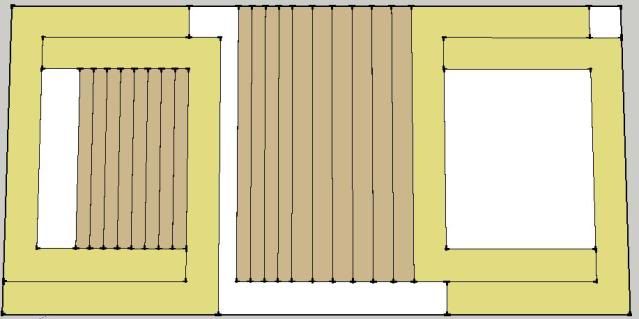

The working height in version 2.0 is approximately 31" which uses a leg panel height of 28", and the width of the sawhorses are nearly 43". The width of a leg panels is 5" which allows you to cut two leg panels out of a 48"x33" section of 3/4" plywood. It may be difficult to understand but I will have a image of the cut list soon which will help clear everything up.

Everything else is the same as the original version.

I built a set of these about three of four weeks ago and have been using them on remodeling and construction jobs and they are holding up great. I have had easily over 100 8' pieces of tongue and groove pine on them along with a miter saw and they never showed any signs of weakness. Everyone who comes to the jobs takes a close look at the sawhorses and asks my boss man where he got them, it feels good when he points at me and says "He built them, not me".

The construction is pretty simple and I think you should be able to simply recreate your own. I did however make a cut list type thing on Sketch up that shows how you can get the pieces easily out of one sheet of plywood.

The "U" shaped leg panels are 28" tall and about 42 15/16" long and 5" wide on all three segments. When it is laid out on a sheet of plywood I center my saw blade on the line since I am using both pieces on either side of the blade.

The rest is pretty easy, 6 pieces 3" x about 42 15/16" (four of them with an 18* bevel cut down one long side) and 4 at 2". Then from the inside of a leg you cut 8 pieces that are used for the inside of the legs for support.

Here is a video helping with the building process. I go into some detail about assembly and remind you of a few things, check it out.

More detailed photo's and descriptions are availiable in this post that should aid in the the building process.

If anyone has and questions of comments feel free. Don't forget about The Woodworking Trip, there should be a video on these things coming soon. Thank you!

12 comments:

This is pretty great. Sturdy and folding!

I like you're design I've been needing some for my shop but lack the space to store them now problem solved....dr.rock29@hotmail.com..............................You can follow me at woodrehab.blogspot.com Come check it out

Very nice design. But two changes I would make:

1. Put a 1 1/2" or so radius in the inside corners of the legs. My engineering mind doesn't like to see inside sharp corners.

2. When adding the beveled side boards to the top, hold the legs at 22" spacing instead of 24", and don't bother with tipping the section off level when fastening them.

do you think 3/4" MDF would work just as well as plywood here?

The mdf will work. But if you may be using these outdoors you'll see some instant damage from any water

I like the simplicity of the design, and will make a pair of these very soon. The interchangeability of the 2x4 is something I have wanted, anf this will allow me to use them for other purposes as well. I am retired, and will not normally need them to travel, but they just might be useful at church as we take care of an older building!

i seen these same saw horses in a magazine years ago and been trying to find which magizine it was so i could make them

i seen the same ones in a magazine along time ago been trying to find so i could build them

Thanks for sharing DIY woodworking video! This will make a great addition to my workplace especially since it is foldable so it makes it easier to store when not in use.

Download Your 150 Free Woodworking Plans

http://bit.ly/150Woodworkingplans

Sara designed a beautiful coffee table inspired by a flower blossom. The wooden table uses veneer timbers from plantation trees such as walnut, maple and zebrano.

Laser engraving can improve the efficiency of engraving, make the surface smooth and smooth, rapidly reduce the temperature of the carved non-metal materials, and reduce the deformation and internal stress of the carved objects. It can be widely used in the field of a fine carving of various non-materials.

CNC Cutting Cutter Machine Engraving Machine for Carved Wooden Furniture

https://amzn.to/3hlQRih

Post a Comment